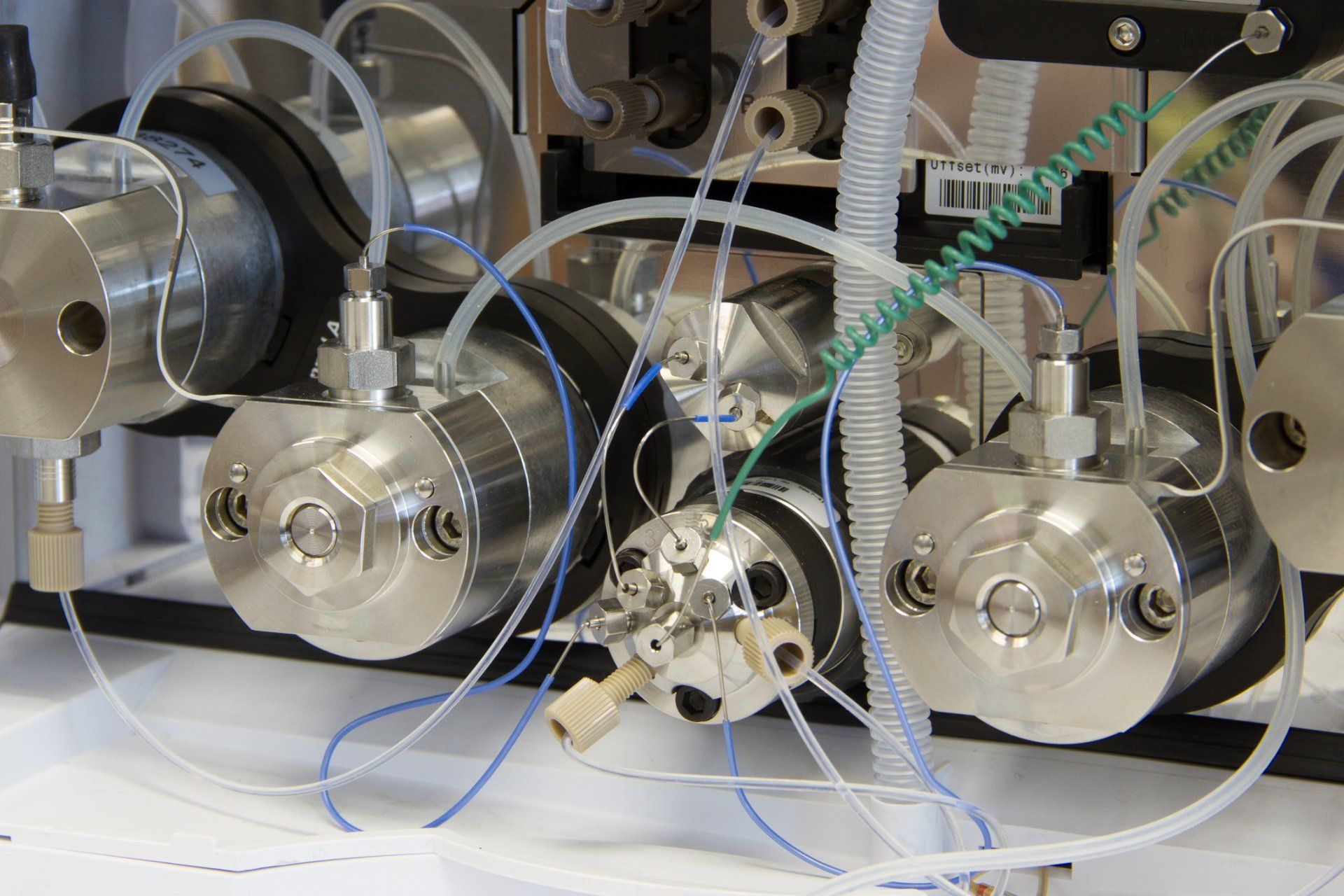

Experts in maintenance and calibration of Chromatography and Tangential Flow Filtration systems

Services

Breakdown Support

GMP

Products

Chromatography & Tangential Flow Filtration Servicing

Service for Performance

-

Read more

Regular preventive maintenance of your equipment is the most efficient way of ensuring optimal performance and reliability. The most complete and convenient way to stay on top of your systems is to enrol in one of our service agreement programmes. Unlike many other lab equipment repair service providers, we do not charge our customers for this.

Your enrolment will provide you with peace of mind, knowing that all your scheduled preventive and corrective maintenance, spare part supply and logistical support will be fully covered, backed by rapid parts acquisition, guaranteed response times and extended telephone technical support.

Preventive Maintenance Support

-

Read more

Ensure continued optimal performance of your ultrafiltration servicing equipment with the assistance and assurance of MAControls service experts. In accordance with cGMP complaint PM protocols written specifically for your equipment, we will:

- Replace all wear parts to ensure consistent process performance.

- Verify calibration with tools which are referenced to national standards.

- Perform a system inspection to anticipate any possible risk of failure.

- Conduct comprehensive functional tests to demonstrate and document that the equipment is in full and proper working order.

Corrective Maintenance and Breakdown Support

-

Read more

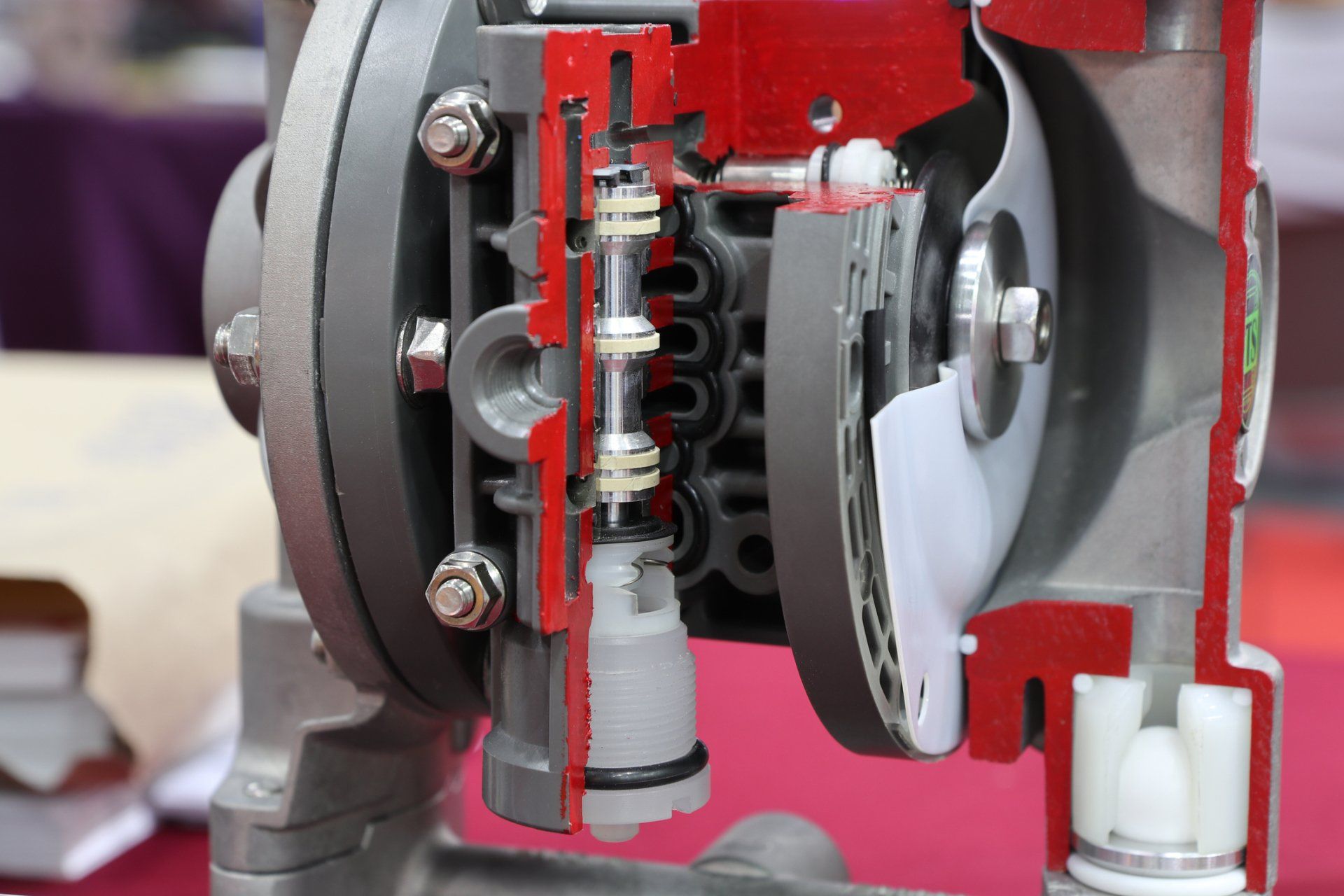

When correctly designed and installed, equipment should operate successfully without problems. However, even the best system may be affected by unpredictable events such as process variations or environmental factors, leading to failure - often at the most critical time. Such events can cause costly downtime, or even the loss of a product batch.

Should you be faced with such a situation, you can depend on MAControls experts to assist your recovery and return you to full operation as quickly as possible.

Risk Analysis

-

Read more

A Risk Assessment ensures that all aspects of potential equipment failure are fully understood and documented. We can provide you with peace of mind, knowing that the adverse consequences of failure are minimised and that a second failure will be prevented.

A physical review adopting an FMEA approach will be performed to consider all the major functional areas of the equipment, identifying all potential points of exposure and including, but not limited to, maintenance frequency, personal training, spare parts strategies and operational procedures.

MAControls will work with you to establish a quote based on the specificity of the equipment and your needs (type of equipment, type of production, type of product, process steps, product stability, spare parts, people competencies) to establish a guarantee that the capital investment you have made is properly maintained for optimum system performance and longevity.

Repair Centre

-

Read more

At MAControls we know that cost is important to clients, and we can save you money in several ways. That’s why we offer our Laboratory Equipment Service Repair Centre, a more economical alternative for servicing lab equipment bench scale or analytical equipment.

By sending or bringing your systems to our repair centre, you save the expense of on-site visits. Have your systems serviced by our trained service engineers to allow you to meet your process demands.

Spare Parts

-

Read more

Any installed process equipment uses components and devices from hundreds of different manufacturers and suppliers (pumps, gauges, elastomers and seals, etc.) Simplify your spare parts supply chain by taking advantage of MAControls’ “one-stop-shop” for all your part support needs.

We can also support annual and multi-year (spare part) material planning to help avoid costly downtime. Further, we can coordinate delivery of your spare parts to align with your scheduled service activity.

All this with the assurance that only the service expertise of MAControls can provide.

Typical equipment coverage

-

Read more

• Liquid chromatography separation systems - small-scale analytical to full production capacity

• Chromatography columns – small-scale analytical scale to 2M hydraulically assisted

• Tangential Flow Filtration Systems including NFF,UF,MF,RO

• Computer and control validation

We regularly service:

• Cytiva Bioprocess systems

• Akta Systems

• Ultrafiltration Systems

• UVis-920 and UV-900 Analysers

• Millipore K-Primes

• Mettler Toledo Systems

We service all makes and models of Cytiva, Millipore, Pall, process and lab scale equipment as well as chromatography columns.

Contact Us

Contact Us

We will get back to you as soon as possible

Please try again later