Calibration Interval

The minimum requirement for GMP systems is a calibration requalification every 12 months.

Many customers increase this to six-monthly, with calibration support and replacement parts. This depends on the frequency that the system is used.

If there is evidence that a particular instrument is regularly outside its specified limits, we strongly recommend that the frequency of calibration is reviewed and increased as appropriate.

A calibration register should be created, defining instrument range, process range, allowable error and calibration frequency. This has to be maintained as a minimum FDA requirement.

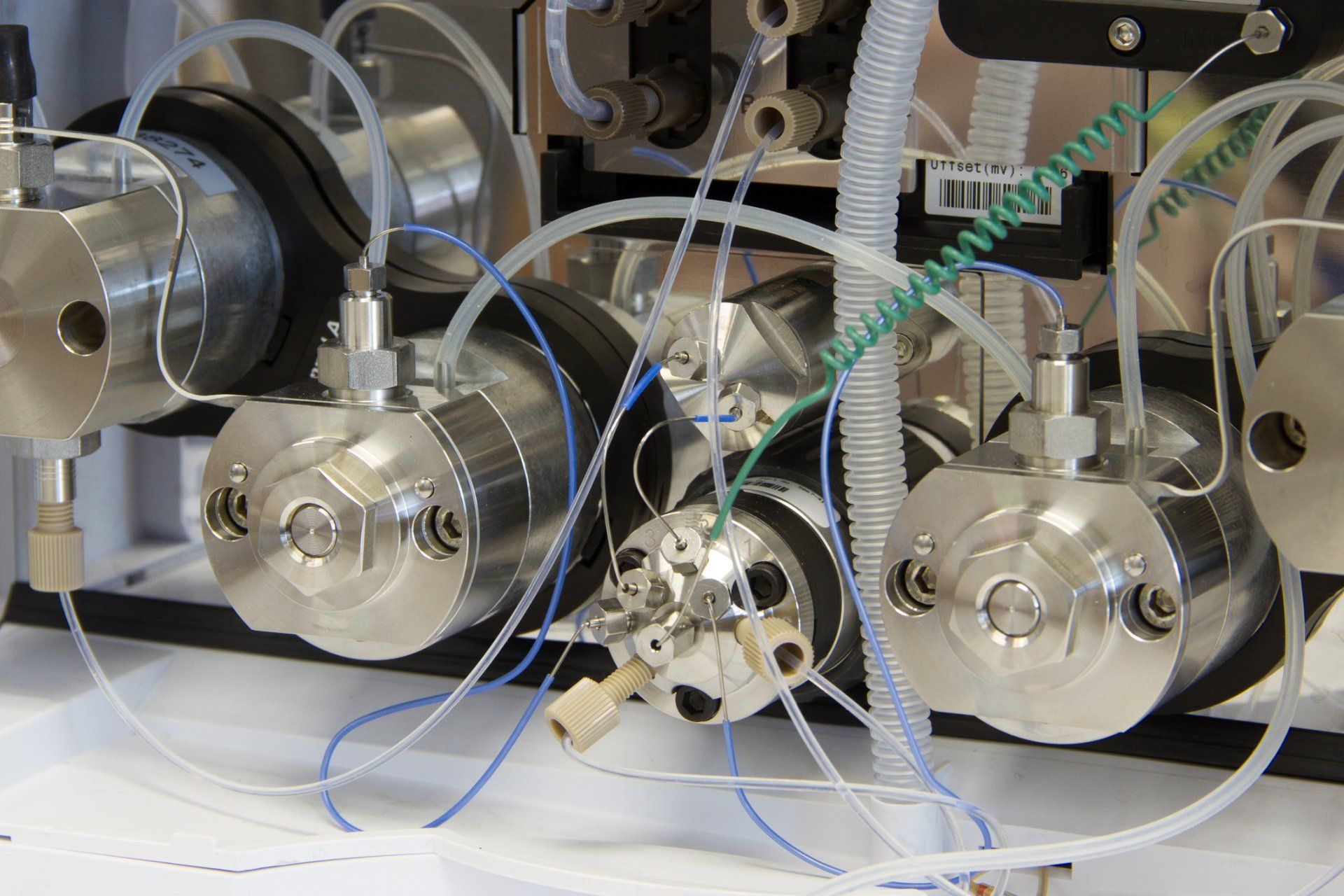

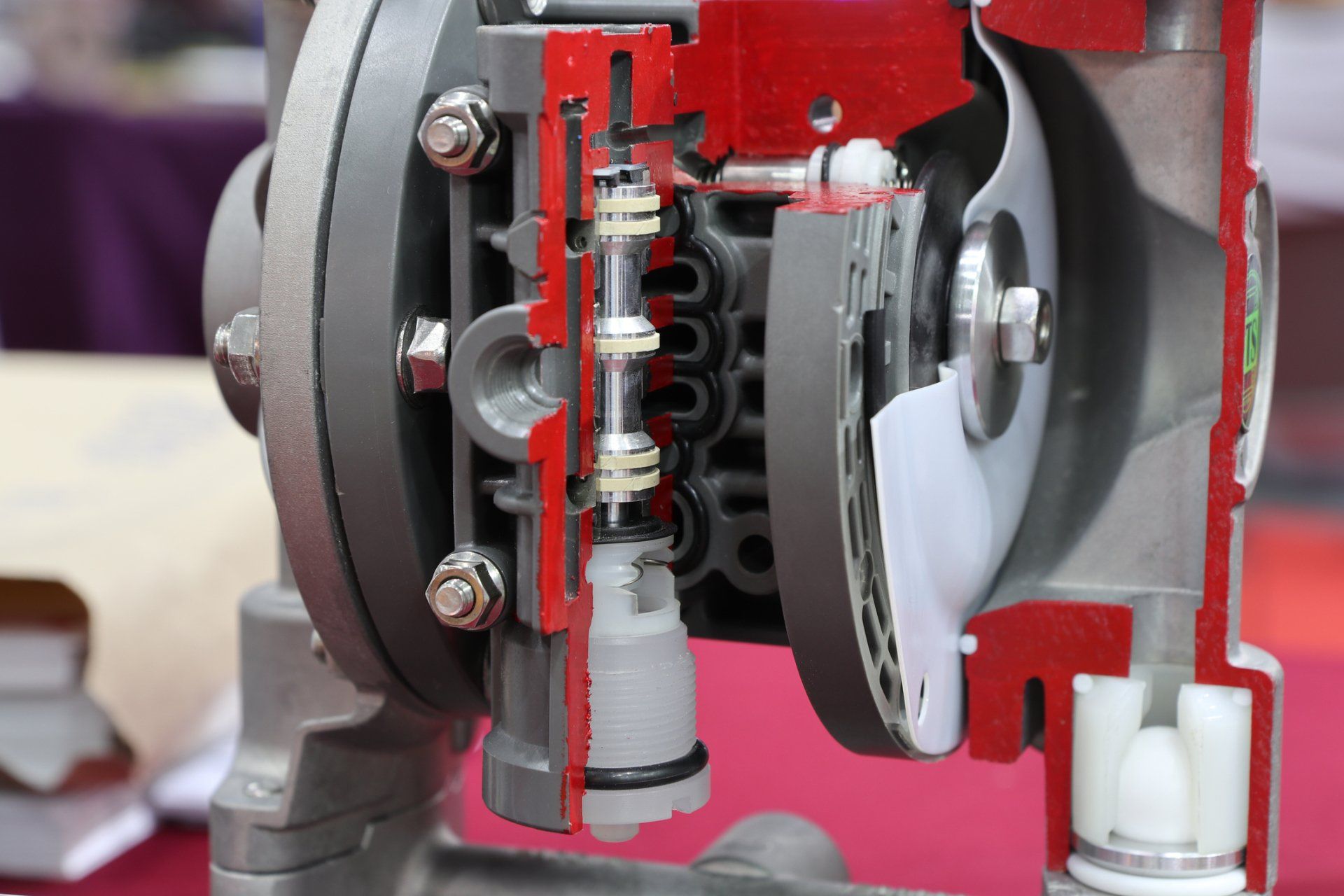

Planned preventive maintenance (PPM)

Some parts are normally replaced regardless of condition, as part of an annual PPM procedure. This enhances the reliability of a system and reduces the risk of failure during production runs. When determining which parts should be replaced, you should consider the following areas:

• Valve diaphragms

• Sanitary seals

• Other seals and O-rings

• Pump seals, check valves and diaphragms

• pH electrodes

• Batteries

Age of systems and other known problems

As systems age, some components may be prone to failure. MAControls holds service records for a large number of process scale Chromatography and UF systems which can be used to identify possible models that might fail.

A risk assessment should be reviewed annually against known failure modes and amended as necessary. Older systems will have a greater risk of failure, or use obsolete components which become difficult to source as spare parts. MAControls have great success sourcing obsolete parts. If not we can provide alternatives.

Documentation

Contact Us

Contact Us

We will get back to you as soon as possible

Please try again later